Advantages of EKOFIBER

- good thermal insulator,

- prevents development of fungi and mould,

- enables diffusion of gases – “breathes”,

- resistant to fire,

- protects the structure against corrosion,

- unfriendly to rodents and insects,

- good sound insulator.

EKOFIBER

IN POLAND SINCE 1994

NORDISKA EKOFIBER POLSKA Sp. z o. o. (NEP) is the first Polish producer of products based on cellulose fiber obtained in the recycling process from newspaper waste. Loose construction thermal insulation with the trade name EKOFIBER® is our main product, it was introduced to the Polish construction market in 1994. By the end of 2016, approximately 1.3 million m3 of thermal insulation produced by NEP had been used in various building structures.

In our work, we pay a lot of attention to being in harmony with the nature that surrounds us. The ecological nature of our products results, among other things, from basing production on secondary raw materials, low energy consumption of production and zero emission of harmful factors to the environment.

Our pioneering activities have been noticed and appreciated with many awards. You are invited to learn the effective and still innovative technology that combines many very positive properties.

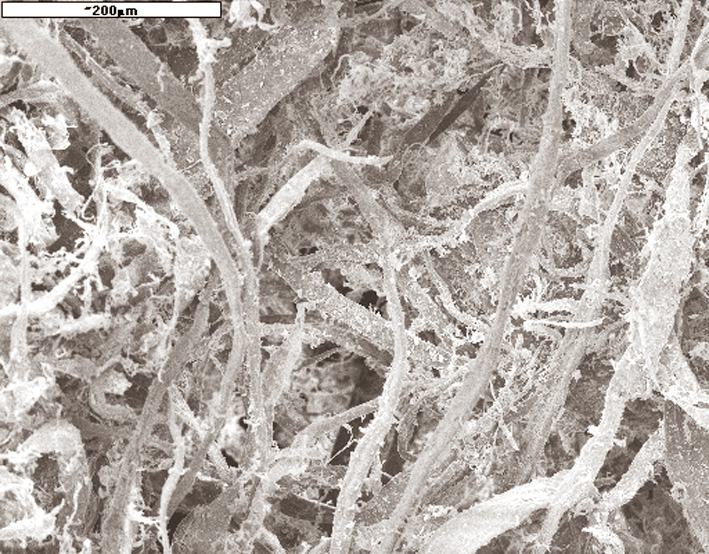

The EKOFIBR production technology is based on secondary processing of newsprint recycled paper.

The cellulose fiber, the main component of the finished product, is recovered from paper. The idea is to guarantee continuous thermal insulation in partitions of building structures, i.e., walls, roof surfaces, flat roofs, and floors. It is possible thanks to its loose, powdery form and application by blowing in. The finished material is packed in 15 kg foil bags on stretched pallets.

We have all the legally required documents allowing it to be used in construction.